LEAN SIX SIGMA

"CAMA National Award Winning Program"

"Coming together is a beginning. Keeping together is progress.

Working together is Success"

Henry Ford, Founder of the Ford Motor Company and Sponsor of Assembly Line

About Lean Six Sigma

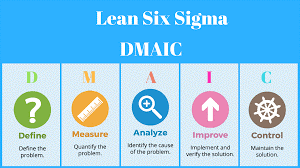

Lean Six Sigma is a method that relies on a collaborative team effort to improve performance by systematically removing waste and reducing variation. Lean is about eliminating the waste and non-value-added activities and Six Sigma focuses on improving process out and quality by identifying and removing the causes of defects and minimizing variability in processes.

CANADA'S BEST LEAN SIX SIGMA FOR GOVERNMENT AND PUBLIC SECTOR ORGANIZATIONS

WHAT IS LEAN SIX SIGMA? Click video below to watch

WHAT ARE THE CORE PROCESSES IN LEAN SIX SIGMA? Click video below to watch

WHAT ARE THE 8 WASTES IN LEAN SIX SIGMA? Click video below to watch

BEE THE CHANGE

The Ontario Municipal Leadership Institute (OMLI) and WSCS Consulting Inc. collaborate closely to design, develop, and deliver Canada’s premier Lean Six Sigma training programs tailored for government and public sector organizations. For over a decade, OMLI and WSCS have been at the forefront of training and certifying hundreds of public sector employees in Lean Six Sigma methodologies.

The Ontario Municipal Leadership Institute (OMLI) and WSCS Consulting Inc. collaborate closely to design, develop, and deliver Canada’s premier Lean Six Sigma training programs tailored for government and public sector organizations. For over a decade, OMLI and WSCS have been at the forefront of training and certifying hundreds of public sector employees in Lean Six Sigma methodologies.

Lean Six Sigma prioritizes customer service and aims to eliminate waste and non-value-added activities in service delivery. As government and public sector roles grow more intricate and citizen expectations rise, there is increasing pressure to streamline services effectively.

Our Lean Six Sigma programs are designed to cultivate a corporate-wide culture of continuous improvement and achieve significant cost savings.

BEE INSPIRED

2023 CAMA AWARD RECIPIENT

PETERBOROUGH COUNTY "PRIME FOR LEAN"

20,001 to 100,000 – Population Category, Peterborough County “Prime for Lean” – Developing a Culture of Continuous Improvement (Click Here to Watch the Award Video). Design, development and delivery of Lean Six Sigma training in partnership with OMLI & WSCS Consulting/PRIME BPM.

20,001 to 100,000 – Population Category, Peterborough County “Prime for Lean” – Developing a Culture of Continuous Improvement (Click Here to Watch the Award Video). Design, development and delivery of Lean Six Sigma training in partnership with OMLI & WSCS Consulting/PRIME BPM.

.

.

Municipal Service Delivery Review Modernization

Municipal Service Delivery Review Modernization

- Developed Service Inventories

- Confirmed mandatory vs. discretionary services

- Ensured policies, practices and program delivery reflect legislative compliance and “best practice”

- Assessed processes and identify areas of efficiency

- Identified opportunities for synergies

- Assessed resource needs & organization

- Analyzed viable services in current state

- Analyzed possible alternatives to SDR

74+ Recommendations for Change including;

74+ Recommendations for Change including; - shared service opportunities

- information technology innovations

- detailed analysis of all financial results, and recommendations for savings; and

- opportunities for policy changes.

Building & Planning

Business Process Modernization

$6M+ IN ANNUAL SAVINGS – ADOPTION OF FULLY PAPERLESS DEVELOPMENT APPLICATIONS PROCESS

$6M+ IN ANNUAL SAVINGS – ADOPTION OF FULLY PAPERLESS DEVELOPMENT APPLICATIONS PROCESS

- 4 Service Delivery Review: Bylaw (Administrative Monetary Penalties), Planning, Building, Human Resources and Payroll Services

- LEAN Six Sigma Training

- Focus groups, interviews and walkthroughs were undertaken to validate current state processes

- Over 80 processes mapped and assisted in the change management strategy which has resulted in significant increase in development and reduced cycle time

- Improved building permit process flow and elimination of any waste. A review of the website and online services was identified as a key objective.

- Optimization of existing resources, including human and technological.

- Increased customer satisfaction with timely inspections.

- Continued ability to meet increasing demand.

- Streamlining and integration of other development approvals, including planning.

- Greater technological integration.

Proven PROSCI Change Management Practitioners and Project Managers who understand that success is based on the “People Side of Change”.

Our competitive advantage is… The delivery of customized training that includes a blend of the principles and methodologies of Lean Six Sigma, Change Management and Project Management.

Public sector organizations today are under constant scrutiny and often rely on traditional cost-cutting strategies such as downsizing or postponing projects, which can negatively impact service quality. Historically, improving services has been seen as a driver of higher costs and the potential for increased taxes.

OMLI and WSCS Consulting are working closely with government agencies across all levels to challenge this mindset by placing a stronger focus on the “customer.” By addressing customer needs and improving their experiences, our partnership guarantees measurable results in cost savings, process improvements, and enhanced operational efficiency.

LEAN SIX SIGMA MASTER BLACK BELT – INSTRUCTOR

Tammy Carruthers, BA CPA, CGA CFE CICA PMP CLSSBB CCA MCITP CISA

WSCS Consultants Inc.

Tammy has a Combined Honours Degree in Economics and Law and is a Certified General Accountant. Tammy is also a Certified Fraud Examiner, a Certified Internal Controls Auditor, a Certified Construction Auditor, a Microsoft Information Technology Certified Professional and a Project Management Professional. Tammy has extensive training in Six Sigma and Lean Six Sigma and is a Certified Lean Six Sigma Black Belt and Six Sigma Master in Financial Services. Tammy has been inducted onto Stanford Who’s Who.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

REASONS FOR CHANGE

OMLI and WSCS Consulting, are working closely with all levels of government and their agencies by shifting the focus on the “customer” with guaranteed results in cost savings, process improvements and efficiencies.

- You have been doing the same thing over and over without any significant improvement – “same old results”.

- Improving services at the same or lower costs, means getting a NEW PLAYBOOK!

- If your objective is to find new capacity within your employees, then you need to direct energy to important services and ELIMINATE the things that DON’T ADD VALUE.

- Shifting your focus on your customer and eliminating the non-value-added activities and business processes does NOT mean reducing quality customer service.

- Re-energizing your organization to get employees excited about what they do will ignite endless possibilities.

- Taking the time to examine the actual work performed will provide valuable insight into proper planning for the future.

FREE WEBINAR Introduction To Lean Six Sigma

DATE: OPEN-ON-DEMAND TIME: I HOUR

This customized webinar has been developed to create an awareness of the means of deploying and the impact of a LEAN Six Sigma initiative as a “Business Process Improvement & Cost Savings Program” for your organization.

OUR HIGH-LEVEL OVERVIEW WILL:

- Increase your understanding of LEAN Six Sigma techniques as business process improvement methodologies.

- Assist you in assessing the overall impact that LEAN Six Sigma can have on your organization.

- Help you to gain an understanding of the role you, as management, must undertake to achieve the greatest level of success.

- Share some examples of how LEAN Six Sigma has re-energized governments and some practical examples of its application and success.

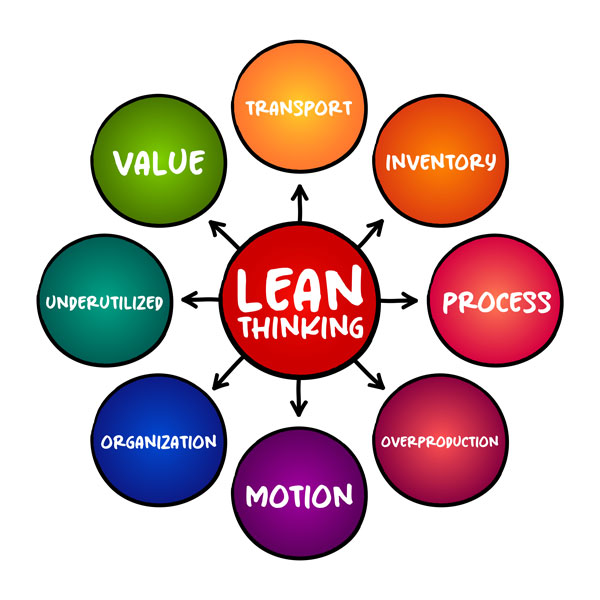

What is “LEAN”?

Lean is a systematic approach to reduce or eliminate activities that don’t add value to the process. Lean ensures customer satisfaction and high quality.

Our Lean Six Sigma Programs Deliver

- Shortened process cycle times

- Faster service delivery

- Reduced or eliminated process defects

- Lower inventory levels

- Optimized resource utilization for greater efficiency

Lean encourages and promotes continuous improvement.

What is “Value”?

“Value” is related to the customer’s perception of the product(s) or service(s), which he or she is willing to pay for.

Lean examines processes based upon the following classifications:

- Non-Value-added Activity: These activities are waste and do not add any value to the process or products.

- Value-added Activity: These activities add value to the process and are essential. They improve processes for productivity and quality.

- Enabling value-added Activity: These activities do not add value and are necessary for the continuity of a process.

- In any process, approximately 85% of activities are non-value adding activities. The aim of the LEAN approach is to identify them in the process and use specific lean tools to eliminate or reduce them.

- Lean is applicable to any organization. A Lean organization improves process efficiencies.

Types of Waste & Waste Removal

As part of our training program, we ensure that employees understand the “value” of a product or service.

Employees will be able to map the value stream, showing the workflow process steps. The value stream mapping helps to identify & eliminate non-value-added activities.

Our training programs assist employees in identifying areas for improvement, reduce the process delays and overall improve the quality of the product/service delivered.

Meet Some of Our Partners

Advancing public and private sector excellence in training, innovation and best practices through

collaboration and strategic partnerships.